Non return plastic spring check valve

Product Description

Product Name: Non return plastic spring check valve

Working Theory

Order to make sure the safety of the drinking water,most countries organizations and countries standards of the piping require that there should install a device on the terminal,which is suitable for guard against flow backwards.Function and structure of KeRuicheck valve core conform to the use standards of guard against flow backwards for most of the countries all over the world.KeRui check valve core is comprehensive used in valve core is comprehensive used in various of pipe valve,faucet,shower and whater meter.It is used in the constant temper ature system to avoid the hot water and cold water mixing.and keep the pressure balance inside the piping as well.

Function-practical Usein

Check valve only allows the water flow to one direction and avoids the water flowing reversely. So it is called unilateralism valve or stop reverse valve as well.

When under the condition of flowing backwards (Reverse Flow),suppose there is pressure increasing backward position of the valve(back pressure condition),or there is pressure decreasing upwward position of the valve(reverse siphon condition),which would cause the reverse pressure,then the check valve will be closed to avoid reverse flow.

When under the condition(Regular Flow),suppose the water pressure is higher than the spring resistance, then the check valve core would open and make the water flow from the one direction valve.

When under the condition at rest,the check valver closes always,that is because the spring pressure make the valve core seal ring closely joint to the check valve, in that case to keep the check valve closing.

| Material | POM Body, EPDM O-Ring, Stainless Steel Spring |

| Color | White |

| Size | 20mm |

| Open Pressure | 0.25Psi |

| Samples Time | 2 days |

| OEM Acceptable | Yes |

| Production Capacity | 1,000,000 pcs each month |

| Packing Details | Poly bag, out carton and pallet. |

| Payment Term | T/T ,PAYPAL,WESTERN UNIOn |

| Delivery Time | 3 days to 5 days after confirming the order |

| Minium Order Quantity | 10pcs |

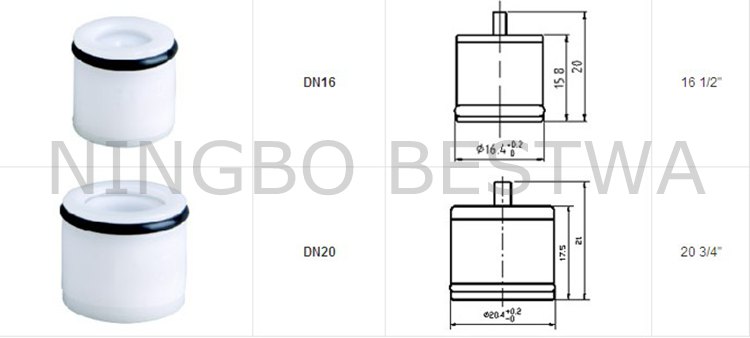

Structure of products:

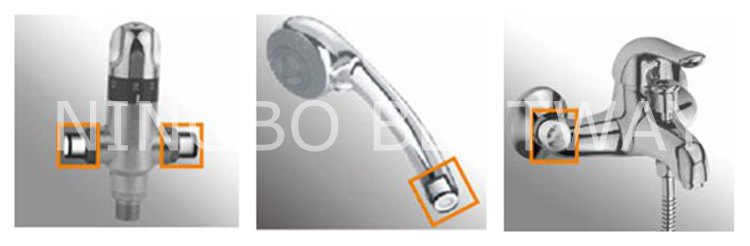

Usage:

Drawing:

Company Information

Ningbo Bestway M&E Limited was set up in June of 1997, with more than ten years of manufacturing experience. We specialize in manufacturing brass & bronze valves and fittings, including ball valves, angle valves, gate valve, check valves, bibcock, tap, fitting, water meter parts and so on. So far, our factory has become one of the leading manufacturers and exporters of valves and fittings in china. We have owned a brilliant team with 10 engineers and technicians, 5quality controller and 150 employees.

We always insisting on the principle of "Competitive price, superior quality, prompt delivery and excellent service makes all customers satisfied".

Welcome to visit our company and do business with us. We sincerely wish to establish long standing cooperation with you. Any of your inquiries will get our close attention.

FAQ

Q:When can I get the quotation?

A:We usually quote within 12 hours after we get your inquiry.If you are very urgent to get the price,pls call us or tell us in your email so that we will regard your inquiry priority.

Q: Could I get samples?

A: Yes,we have materials in stock to help you to get the samples as soon as we can.

Q:Can you do the design for us?

A:We have a professional team having rich experience in manufacturing.We could supply customized size,grade of material,and the coating.We also could supply the package according to your request.

Q.How are orders packed and shipped ?

A: For custom order, we can design full-color custom packaging to match your brand, if requires. Most shipments include boxes packed inside an outer carton and placed on a wooden pallet.

Q:What abount the lead time for mass production?

A:Honestly,it depends on the order quantity and your specific requirements of products.

Q.What are your quality control procedures?

A: We adhere to strict quality control procedures that begin with product design and carry through to the end of the production process using state-of -the-art quality control equipment.